Zinc Pretreatment Products

Order SafeGard products directly from Sanchem

Sanchem offers 3 RoHS compliant pretreatment products for zinc passivation and as a conversion coating paint base: SafeGard CC-3400, SafeGard CC-13062 and SafeGard CC-8400Zn. SafeGard CC-8400 is a RoHS compliant chromate-free conversion coating and passivation treatment for zinc, zinc alloys, zinc plating, galvanized steel and silver. SafeGard CC-8400Zn is a cold-applied, colorless, inorganic coating that has the passivation performance of chromate and requires only a single application tank. This product applies in less than 1 second, passes the copper sulfate test, will not dry out, is unaffected by heat and is economical to use. Aside from exceptional performance this product can be easily integrated into standard galvanizing lines during annual maintenance shutdowns. SafeGard CC-8400Zn can be applied either in the quench tank or at room temperature the end of the process line.

SafeGard CC-8400 features:

- Easy one step treatment- processes just after hot dip galvanizing

- Prevents formation of white rust, often referred to as "storage stain".

- Cold-applied

- Reacts in one second or less

- Film not sensitive to heat and will not dry out

- Thin films less then (400 - 500 nm)

- Prevents reaction of zinc with wet concrete

- Economical

- Practically invisible

- Paintable surface

- Passes copper sulfate test

Click here to download more information about SafeGard CC-8400

Galvanized metal & prevents zinc corrosion and is RoHS Compliant

Chrome-free SafeGard CC-3400

Why you should use SafeGard CC-3400 on zinc plating, zinc die cast, & galvanized metal:

- Meets ASTM Standard B-940-05, Non-Chromate Conversion Coatings on Zinc Surfaces.

- Salt Spray ASTM B-117: Over 300 hours zinc plating, galvanized steel and over 300 hours zinc castings (when used with SafeGard CC-4000 seal).

- Chemically and UV stable

- Gold color

- Easy to use and monitor

- Conductive

- Excellent paint pretreatment

- Electrically conductive

- Excellent corrosion resistance: humidity, salt spray and UV Stable

- Paint adhesion: Passes both wet tape & dry tape tests. (Qualicoat Approved)

- Easy to use and maintain, no sludge will builds up in tank.

- Perfect for high temperature applications –doesn’t breakdown when heated.

- RoHS Compliant pretreatment - SafeGard CC is completely chromium free.

- Economical – one gallon of SafeGard CC concentrate can treat 10,000 ft2 of zinc!

- Heating will not affect chromate-free SafeGard CC conversion coating. This is due to the fact that SafeGard CC reacts to the zinc surfaces at the molecular level it is not a surface coating. It is a true conversion coating.

- SafeGard 13,062 is a conversion coating for use on zinc, zamac, and galvanized metal. This leaves a clear colored surface that prevents zinc oxide formation due to humidity. This product is used before painting.

- SafeGard CC - Seal#10 - Enhances paint and coating adhesion specifically from corrosion on zinc castings

- SafeGard CC - Seal#3 – Heat curable pretreatment for zinc and galvanizes steel. Upon reacting a golden brown colored protective coating is left on the surface. See picture below:

"SafeGard 8400Zn" is the non-chromate white rust preventive for galvanized steel. This dry in place, chemical conversion coating reacts with the zinc surface to form a highly protective colorless film on galvanized metal, zinc and zinc alloys.

ADVANTAGES

- Prevents the rapid formation of the white film of zinc oxide that forms on galvanized sheet steel, galvannealed, galvalume, and other zinc plated materials.

- Contains no toxic chromate, cyanide or fluoride, thus it is easy to dispose.

- Excellent paint base. Gives filiform performance equal to that of chrome-chromate coatings.

- High corrosion performance can allow you to get the same corrosion performance using a thinner galvanized coating with SafeGard CC-8400Zn as thicker zinc galvanized coatings. A major cost savings.

- No sludge build up in the tank

Additional coatings for zinc and galvanized steel:

SafeGard 13,062 is a conversion coating for use on zinc, zamak, and galvanized metal. This leaves a clear colored surface that prevents zinc oxide formation due to humidity. This product is used before painting.

SafeGard CC - Seal#10 - Enhances paint and coating adhesion specifically from corrosion on zinc castings

SafeGard CC - Seal#3 – heat curable pretreatment for zinc and galvanized steel. Upon reacting a golden brown colored protective coating is left on the surface. See picture below:

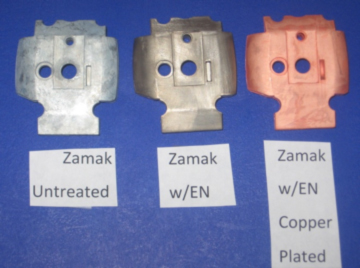

SafeGard CC - Plating Catalyst can replace traditional time consuming zincate and copper strikes before electrolysis nickel.

For more severe environments the use of electroless nickel base can increase the life of a zinc part dramatically.

Zinc Casting

Zinc Casting

Zinc Casting with Sanchem’s Plating Catalyst & Electroless Nickel

Zinc Casting with Sanchem’s Plating Catalyst & Electroless Nickel

For additional coating options on zinc and zamak: EN, copper, or chrome plated

Use SafeGard CC when RoHS compliance and YOUR company's product performance are important.