Water Tanks Corrosion Protection

Easy to use NO-OX-ID rust preventive coatings have been preventing corrosion in metal tanks for over 100 years. Preventing rust and corrosion does not require an expensive complex multi-coating system that can only be applied correctly by an expert under ideal laboratory conditions. NO-OX-ID’s are complex corrosion control products that are simple to use in real-life conditions by even novice applicators.

NO-OX-ID A-Special WW is NSF-61 approved for drinking water and is completely insoluble in water; therefore it imparts no taste, odor or color to water. NO-OX-ID is the high performance, safe, reliable & low price/coat alternative to high priced paints.

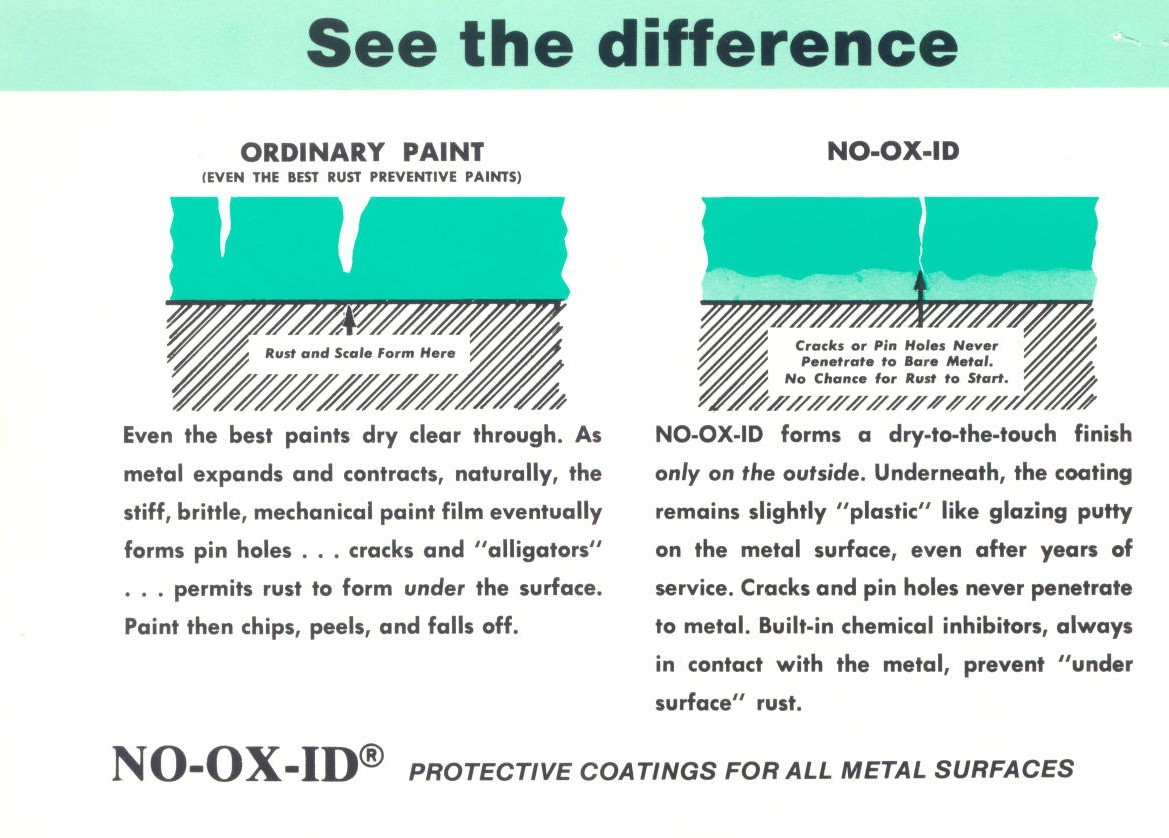

Why use NO-OX-ID over standard paint coatings?

- Surface preparation: With NO-OX-ID you only need to prepare the surface using a power wire brush or scrapers to remove loose paint or rust. Whereas most paint requires an SSP#10 commercial sandblast. This saves you time & money!

- NO-OX-ID is a one coat rust preventive system. The standard coating thickness in a tank is 20-30 mils, but you can apply thicker if higher corrosion performance is desired. This product saves you money & a minimum out of service time.

- Minimum downtime: Tanks can be put back in service 24 hours after coating with Sanchem NO-OX-ID “A Special WW”. Whereas, epoxies and vinyl might take as long as 7 to 10 days to cure before water can be put back into the tank.

- Ease of application: NO-OX-ID can be applied by brush, roller or airless spray equipment.

NO-OX-ID A-Special WW is NSF-61 approved for drinking water because NO-OX-ID imparts no taste, odor or color to water.

NO-OX-ID is used to fix failing paint coating applications: When a paint coating system in a tank gets a crack the paint company always recommends a costly complete tank recoat, are there any options? Yes, many companies who have that problem decided just do a low-cost touch-up the bad areas with NO-OX-ID. They just power brush the areas needed to be repainted and apply NO-OX-ID.

NO-OX-ID coatings are self-healing and leave a non-drying, plastic-like film that will not crack, chip or peel.

This NSF-61 approved steel rust inhibitor imparts no taste or odor to the water supply. For water storage tanks, we recommend a coating thickness of 20-30 mils. Contractors who apply NO-OX-ID rust preventative coating usually give a 3-5 year unconditional performance guarantee. How can they do this? They have over 60 years of firsthand experience using NO-OX-ID's and this performance record means there is no risk!

For over 60 years, these products have been used by utilities to prevent corrosion of buried pipes, valves, potable water storage tanks and as a lubricant inside of water filtration plants.